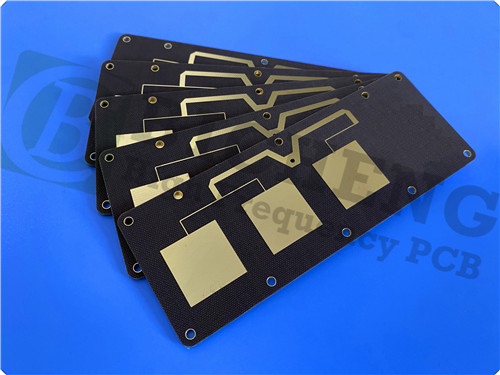

TLX-8 PCB 2-Layer 30mil High-Frequency PTFE Fiberglass Laminates for Radar and Mobile Communications

1. TLX-8 Introduction

TLX-8 is a type of PTFE fiberglass laminate designed for high-volume antenna applications, delivering reliability across various RF uses. This versatile material is available in numerous thicknesses and copper cladding options, making it suitable for low-layer microwave designs. It offers mechanical reinforcement in challenging environments, such as:

- Resistance to creep for printed wiring boards (PWBs) attached to housings that experience significant vibration during space launches.

- Durability under high temperatures in engine modules.

- Radiation resistance suitable for space applications (refer to NASA’s guidelines for low outgassing materials).

- Robustness in extreme maritime conditions for warship antennas.

- Stability across a wide temperature range for altimeter substrates during flight.

2. Benefits

- Outstanding passive intermodulation (PIM) values in PCBs (measured below -160 dBc).

- Superior mechanical and thermal properties.

- Low and stable dielectric constant (Dk).

- Exceptional dimensional stability.

- Minimal moisture absorption.

- Tightly controlled dielectric constant.

- Low dissipation factor (DF).

- UL 94 V0 rating.

- Ideal for low-layer microwave designs.

3.Main Properties

- Electrical Properties

Dielectric Constant @ 10 GHz - 2.55 ¡À 0.04 - IPC-650 2.5.5.3

Dissipation Factor @ 10 GHz - 0.0018 - IPC-650 2.5.5.5.1

Surface Resistivity Elevated Temp. 6.605 x 10^8 Mohm IPC-650 2.5.17.1 Sec. 5.2.1

Surface Resistivity Humidity Cond. 3.550 x 10^6 Mohm IPC-650 2.5.17.1 Sec. 5.2.1

Volume Resistivity Elevated Temp. 1.110 x 10^10 Mohm/cm IPC-650 2.5.17.1 Sec. 5.2.1

Volume Resistivity Humidity Cond. 1.046 x 10^10 Mohm/cm IPC-650 2.5.17.1 Sec. 5.2.1

- Dimensional Stability

MD After Bake 0.06 mm/M (mils/in) IPC-650 2.4.39 Sec. 5.4

CD After Bake 0.08 mm/M (mils/in) IPC-650 2.4.39 Sec. 5.4

MD Thermal Stress 0.09 mm/M (mils/in) IPC-650 2.4.39 Sec. 5.5

CD Thermal Stress 0.10 mm/M (mils/in) IPC-650 2.4.39 Sec. 5.5

- CTE (25-260 ¡ãC)

X - 21 ppm/¡ãC - IPC-650 2.4.41/ASTM D 3386

Y - 23 ppm/¡ãC - IPC-650 2.4.41/ASTM D 3386

Z - 215 ppm/¡ãC - IPC-650 2.4.41/ASTM D 3386

- Td

2% Weight Loss - 535 ¡ãC - IPC-650 2.4.24.6 (TGA)

5% Weight Loss - 553 ¡ãC - IPC-650 2.4.24.6 (TGA)

-Chemical / Physical Properties

Moisture Absorption - 0.02 % IPC-650 2.6.2.1

Dielectric Breakdown - > 45 Kv - IPC-650 2.5.6

Flammability Rating - V-0 - UL-94

4. PCB Stackup: 2-layer rigid PCB

- Copper Layer 1: 35 µm

- Taconic TLX-8 Core: 0.762 mm (30 mil)

- Copper Layer 2: 35 µm

5. PCB Construction Details

- Board Dimensions: 85 mm x 77 mm (1 piece, ± 0.15 mm)

- Minimum Trace/Space: 5/5 mils

- Minimum Hole Size: 0.3 mm

- No blind vias.

- Finished Board Thickness: 0.8 mm

- Finished Copper Weight: 1 oz (1.4 mils) on outer layers

- Via Plating Thickness: 20 µm

- Surface Finish: Immersion Gold

- Top Silkscreen: White

- Bottom Silkscreen: None

- Top Solder Mask: None

- Bottom Solder Mask: None

- 100% electrical testing conducted before shipment

6. PCB Statistics:

- Components: 26

- Total Pads: 48

- Through Hole Pads: 25

- Top SMT Pads: 23

- Bottom SMT Pads: 0

- Vias: 32

- Nets: 2

7. Type of Artwork Supplied:Gerber RS-274-X

8.Quality Standard:

IPC-Class-2

9. Availability: Worldwide

10. Some Typical Applications

- Radar systems

- Mobile communications

- Microwave test equipment

- Microwave transmission devices

- Couplers, splitters, combiners, amplifiers, and antennas